In the world of construction, manufacturing, and engineering, the importance of small yet essential components like nuts and fasteners often goes unno

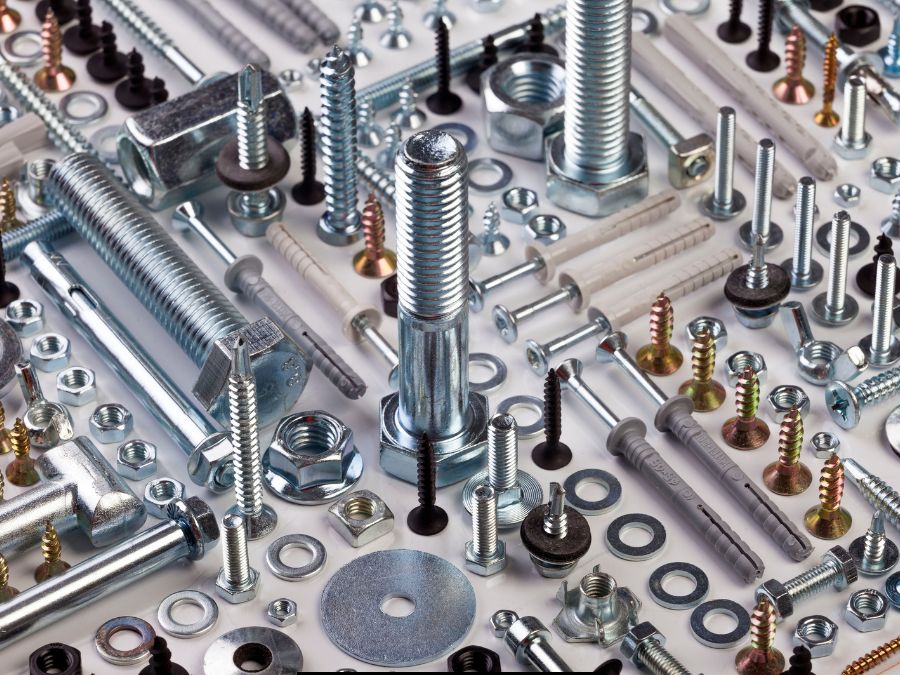

In the world of construction, manufacturing, and engineering, the importance of small yet essential components like nuts and fasteners often goes unnoticed. Despite their size, they form the backbone of countless structures and machinery, ensuring stability, durability, and functionality. Let’s dive into the world of nuts and fasteners to understand their significance, types, applications, and how to choose the right ones for your needs.

What Are Nuts and Fasteners?

Nuts and fasteners are hardware devices used to join two or more objects together. While a nut is typically paired with a bolt to secure components, a fastener encompasses a broader range of devices, including screws, bolts, rivets, and washers. These components are critical for creating non-permanent joints, allowing disassembly and reassembly when needed.

Types of Nuts

Nuts come in various shapes and sizes, each designed for specific applications. Here are some common types:

- Hex Nuts:

- The most commonly used type.

- Features a six-sided shape for easy wrench application.

- Wing Nuts:

- Equipped with protruding wings for hand tightening without tools.

- Ideal for quick assembly and disassembly.

- Lock Nuts:

- Prevent loosening under vibration or torque.

- Examples include nylon-insert lock nuts and jam nuts.

- Cap Nuts:

- Have a domed top to cover the exposed end of a bolt for safety and aesthetic purposes.

- Flange Nuts:

- Feature a built-in washer for better load distribution.

- Often used in automotive and industrial applications.

Backlink Links

Types of Fasteners

Fasteners also come in a variety of forms, designed to meet diverse requirements:

- Bolts:

- Paired with nuts for secure joints.

- Available in various grades and materials.

- Screws:

- Self-threading fasteners ideal for wood, metal, or plastic.

- Rivets:

- Permanent fasteners used in structural applications.

- Commonly seen in aerospace and construction.

- Washers:

- Used to distribute load and prevent damage to surfaces.

- Threaded Rods:

- Long rods with threading along their length for versatility in construction.

Materials Used in Nuts and Fasteners

Nuts and fasteners are made from a range of materials to meet specific demands:

- Steel:

- The most common material, offering strength and durability.

- Often coated with zinc or galvanized for corrosion resistance.

- Stainless Steel:

- Highly resistant to corrosion, making it suitable for outdoor and marine applications.

- Brass:

- Corrosion-resistant with an attractive finish, often used in decorative applications.

- Titanium:

- Lightweight yet incredibly strong, used in aerospace and high-performance industries.

Applications of Nuts and Fasteners

The versatility of nuts and fasteners makes them indispensable across industries:

- Construction:

- Securing beams, columns, and frameworks.

- Automotive:

- Ensuring the integrity of engines, wheels, and body parts.

- Aerospace:

- Used in critical areas where strength and weight reduction are paramount.

- Electronics:

- Assembling circuit boards and casings.

- Home Improvement:

- DIY projects and furniture assembly.

How to Choose the Right Nuts and Fasteners

Selecting the appropriate nuts and fasteners involves several considerations:

- Material Compatibility:

- Ensure the materials of the fastener and the components being joined are compatible to prevent galvanic corrosion.

- Load Requirements:

- Understand the mechanical load and choose a fastener with the appropriate tensile strength.

- Environmental Conditions:

- Opt for corrosion-resistant materials in outdoor or marine environments.

- Thread Size:

- Match the thread size and pitch for a secure fit.

- Application-Specific Design:

- Use specialized fasteners like locking nuts or flanged bolts for unique requirements.

Innovations in Fastening Technology

The fastener industry continues to evolve with advancements in materials and design. Self-locking mechanisms, corrosion-resistant coatings, and lightweight materials like composites are just a few examples of how modern engineering is enhancing the performance of nuts and fasteners.

Conclusion

Though often overlooked, nuts and fasteners are integral to the functionality and safety of countless applications. By understanding their types, materials, and uses, you can make informed decisions to ensure the success of your projects. Whether you’re building a skyscraper or assembling a piece of furniture, these tiny components play a monumental role in holding it all together.

COMMENTS