Have you ever seen the cautionary sign posted outside an electrical transformer or an enclosure covered in big wires and cables? The repeated images o

Have you ever seen the cautionary sign posted outside an electrical transformer or an enclosure covered in big wires and cables? The repeated images of thunderbolts should serve as ample warning: avoid high voltage! Even when safety is available, it is essential to understand everything there is to know about voltage power and why you should not ignore it.

“High voltage” is used to describe voltage power levels that are above the usual standard or threshold. High voltage’s two main characteristics are that it produces sparks that fly through the air and that it can shock anybody who comes too close to it. The voltage may be between a conductor and the ground or between two conductors in a system. For instance, any voltage over 35,000 volts is regarded as high voltage when it comes to the transmission of electric power. It is crucial to consider the insulation and design of the apparatus while classifying it.

Because any voltage above 50 volts is unsafe for living things, it is important to include more safety and make sure that the circuits themselves follow safety regulations. High voltage also refers to any voltage that is over 1000 volts. In light of this, extra-high voltage, or EHV, is defined as voltages that fall between 345,000 and 765,000 volts. It may vary according to HV Cable Suppliers.

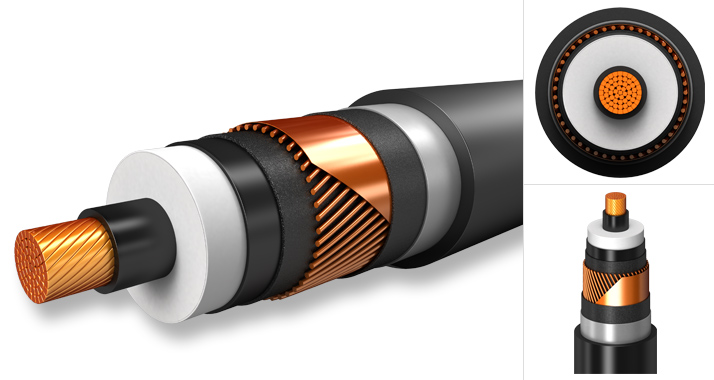

Knowing the actual and physical power of high voltage makes it simple to remember how it operates and is built. For the transmission of electric power, a particular high-voltage power cable is needed because individual conductors carry high voltage. For a standard high-voltage power cable, the following is necessary:

Conductor

Insulation can be applied both above and below the water

ensuring that the high voltage effect is controlled and doesn’t cause the insulation to fail in the cable and joints

High-voltage cables come in a variety of types to suit various uses. Some are essential for the operation of instruments, the transmission of AC and DC power, and ignition systems. To avoid any interaction between other items or living things and a high-voltage conductor, high-voltage power cable systems are used. Additionally, its leakage current needs to be properly managed and observed.

Even when there is a spike in high voltage caused by electric discharges produced by ozone in the air, the insulation of a high-voltage power cable must be adjusted. A layer of a metallic shield on the insulation, connected to the ground, must cover every cable connector and joint. This metallic shield is utilized to balance the insulation-containing dielectric stress layer.

Design and Construction of High-Voltage Power Cables

High-voltage power cables have a few unique characteristics and are designed to function with particular switching and distribution panels.

They make it possible to manually or remotely switch and control rooms for the testing of individual supply systems.

High-voltage power cable substations have the ability to reduce the voltage in an effort to distribute it to nearby locations.

The semiconducting layers should be a few micrometers thick and smooth. Any fission or gap between the layers’ fusion and insulation can be extremely hazardous.

The structure of a high-voltage power cable includes one or more conductors, suitable insulation, and a protective jacket. In order to control the electric field in the conductor, the number of layers in the insulation jacket of the cables may vary depending on the voltage power level.

Conductors that operate at voltages higher than 2,000 volts frequently employ high-voltage power cables. With this amount in mind, each insulator and conductor will have a conductive shield that aids in distributing electrical stress.

“Stress relief cones” are mounted at the ends of shields.

100,000-volt power distribution cables have good oil and paper insulation. They work by using a stiff steel pipe and a coating made of rigid or semi-rigid aluminum or lead.

Applications of High-Voltage Cable

Since HV power cables are unique, they can be found in switching and distribution panels. With these cables, you can also control rooms from afar or by hand when you need to test each supply system. People also use these cables when they work closely with raw materials and triple extrusion systems. In the future, these cables will be used in power circuits where the line-to-ground fault current is less than a certain amount. Even in places that are dry or wet, these cables are set up in cable trays, ducts, and raceways.

At Znergy Cable, the team uses only the best technology to make cables that can go up to 220KV.

You should choose high-voltage cables for many reasons. First of all, these cables are made with a process called triple-layer extrusion. During the manufacturing process, the team uses technology with XLPE or EPR insulation and a semiconducting bonded conductor screen across the semiconducting layer. This makes the cables last longer and makes it less likely that they will break. When the team uses XLPE insulation, it helps improve the mechanical and electrical performance and has a low dielectric factor.

High Voltage Cable Manufacturers in Australia: Znergy Cable

A high-voltage cable is a type of electrical wiring that is made to send high-voltage power, which is dangerous because of how much energy it contains. High-voltage electricity can be found in the lines that bring electricity to homes and businesses, as well as in systems that use a lot of electricity, like some industrial machines. Electricity needs to be sent through the wires in a safe and effective way, with as little risk to the system and people as possible.

Znergy Cable is one of the best High Voltage Cable Manufacturers in Australia. With a wide range of high-quality electrical cables, we set a standard in Australia.

Contact us for the best electrical cables.